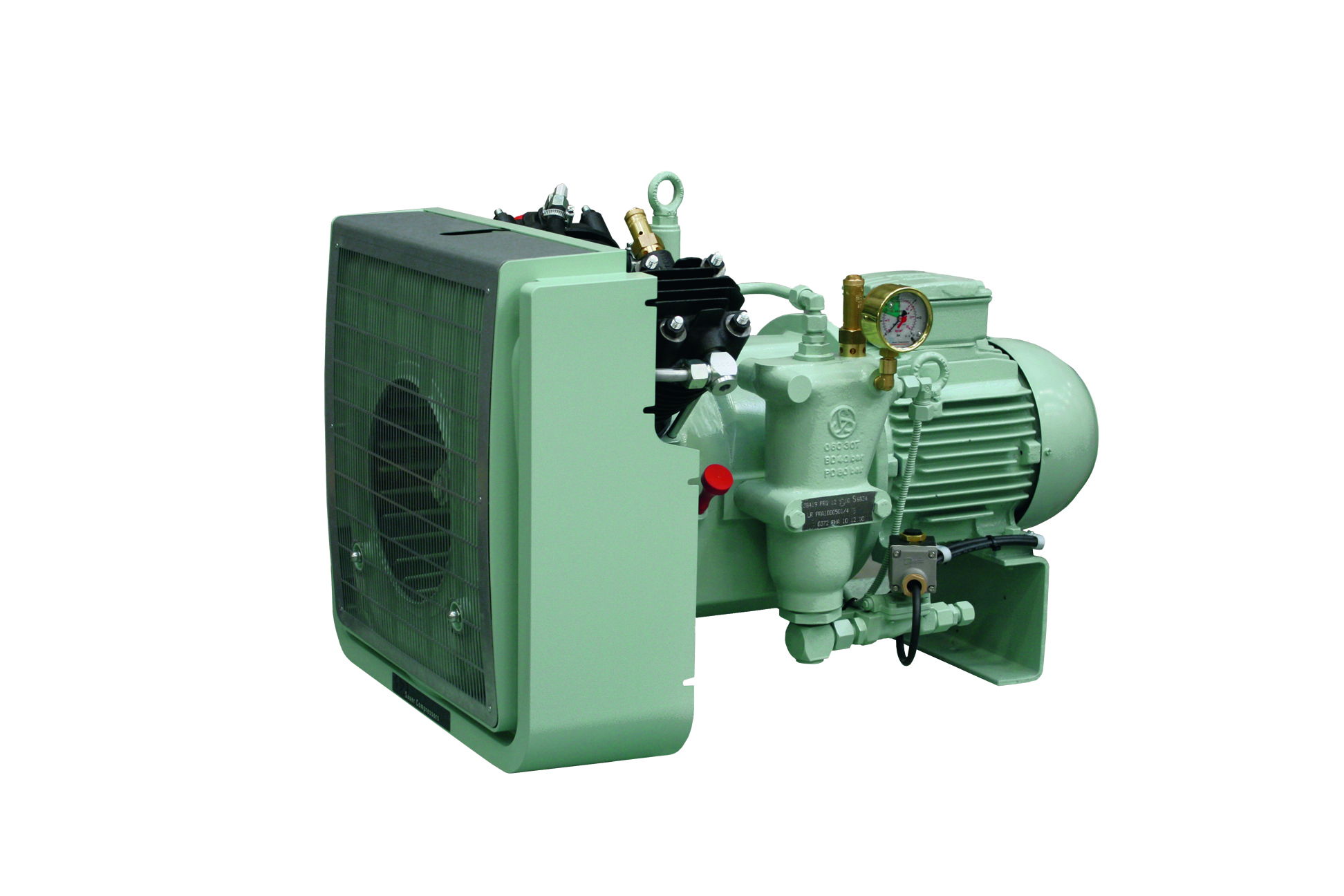

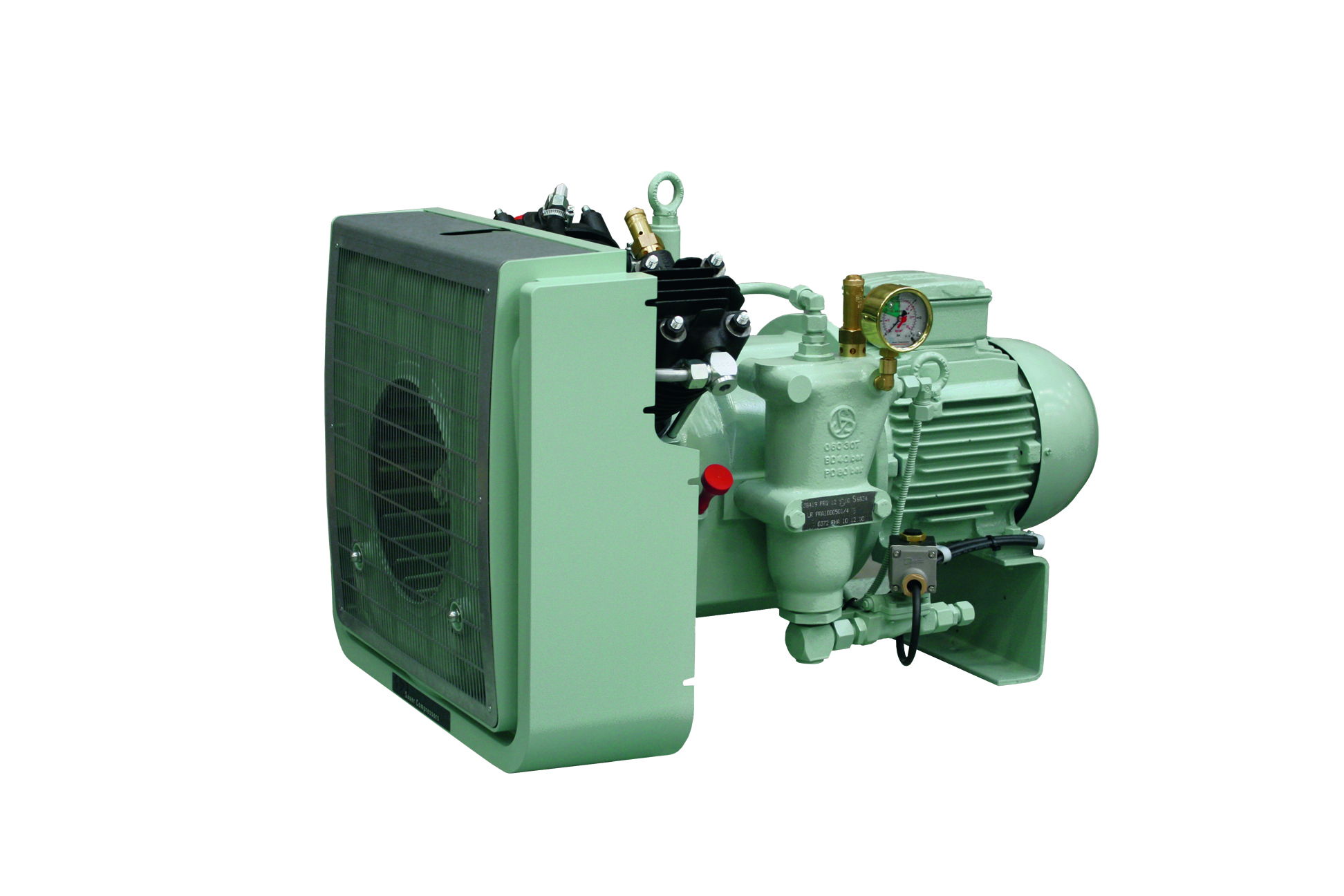

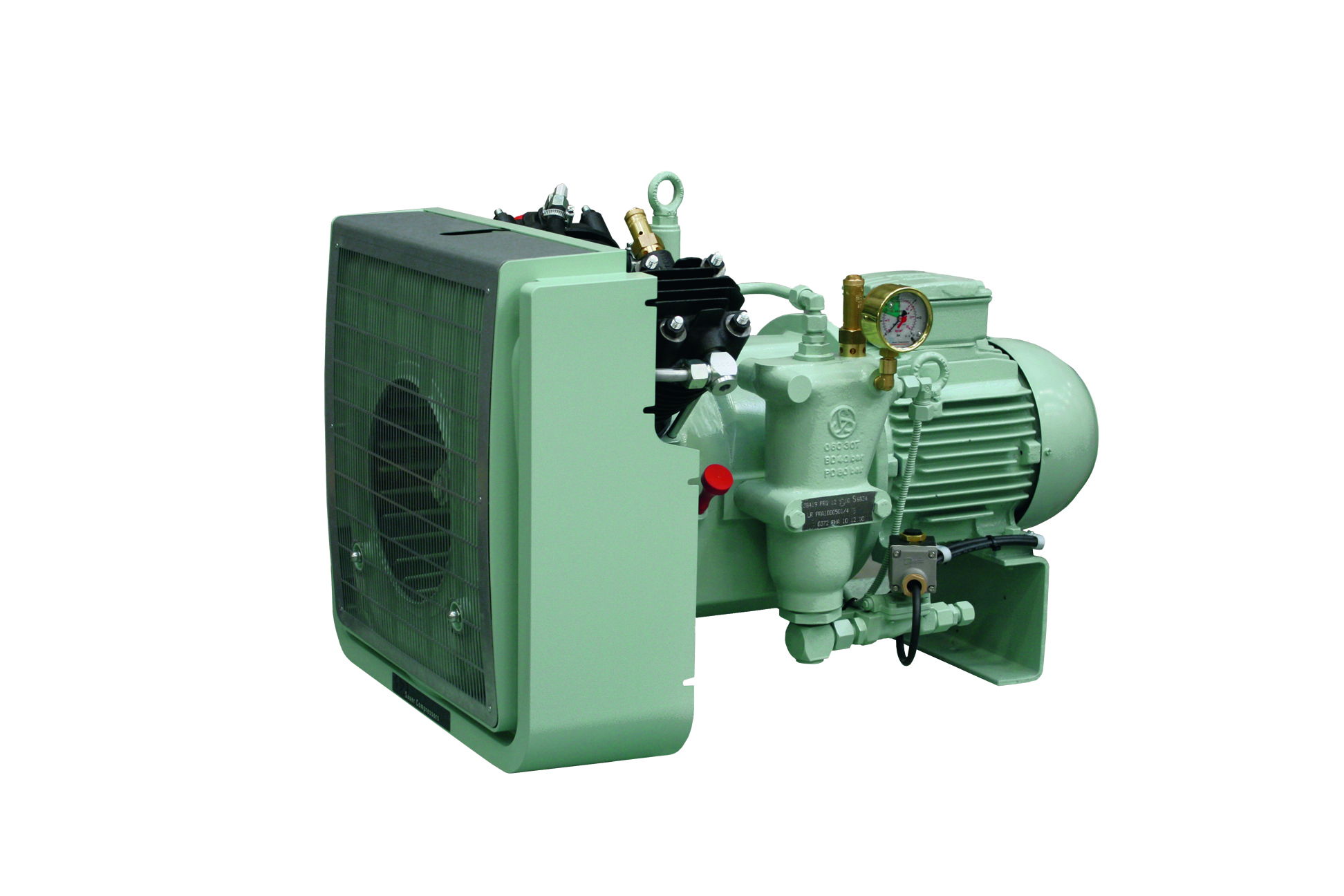

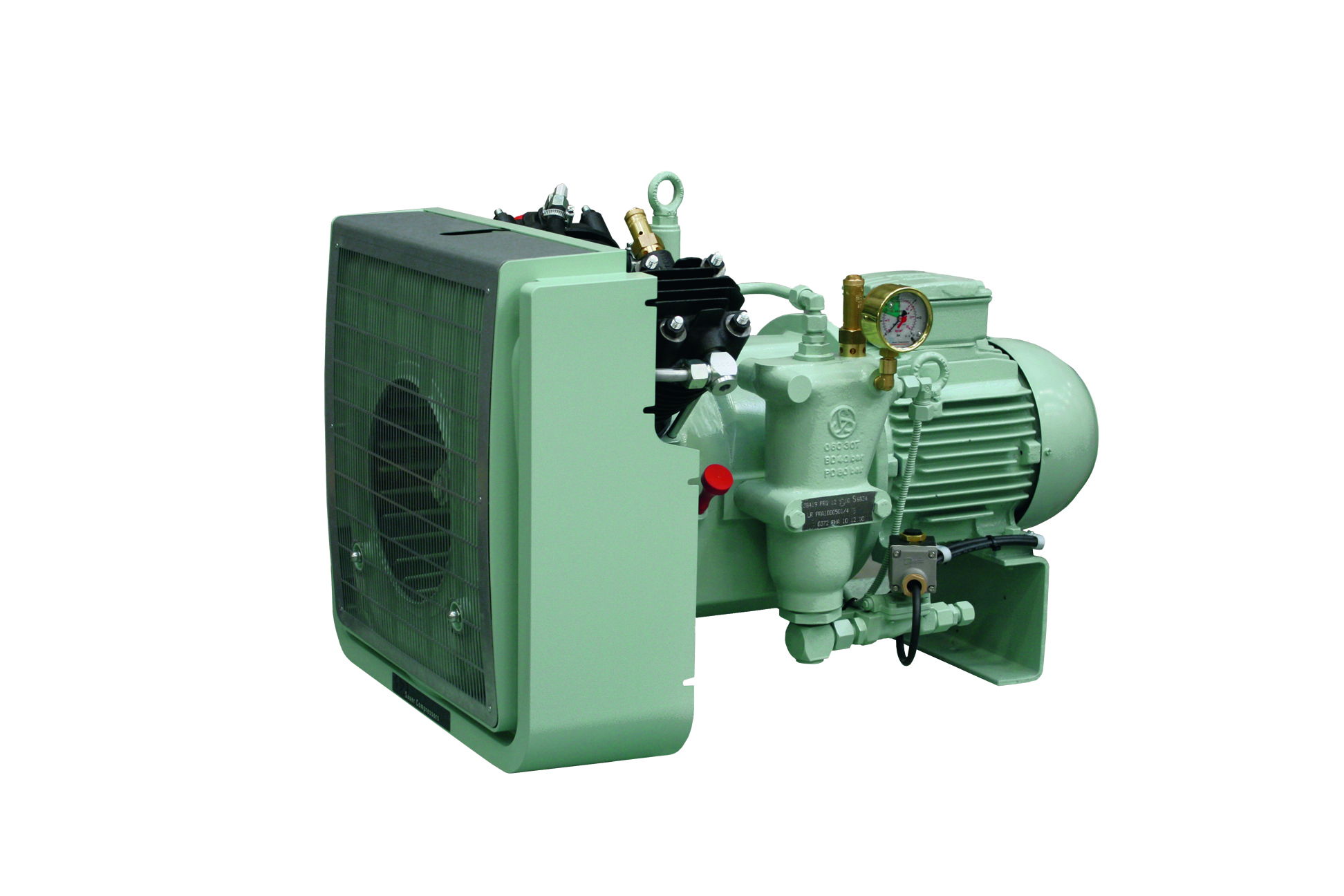

Pressure: 10 – 40 barg Volume Flow: 8 – 80 m³/h Rated Power: 3 –18.5 kW Media: Air, Nitrogen

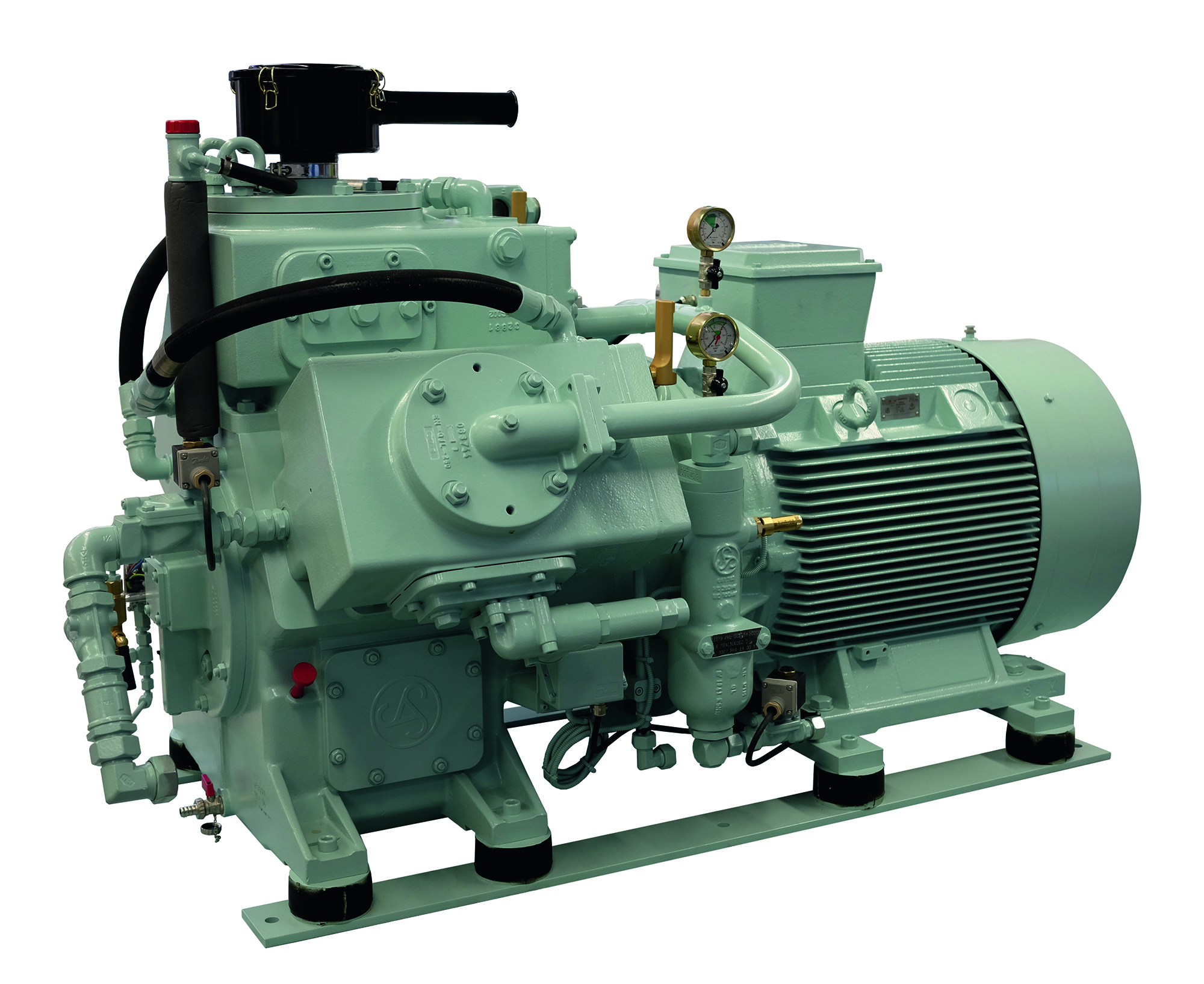

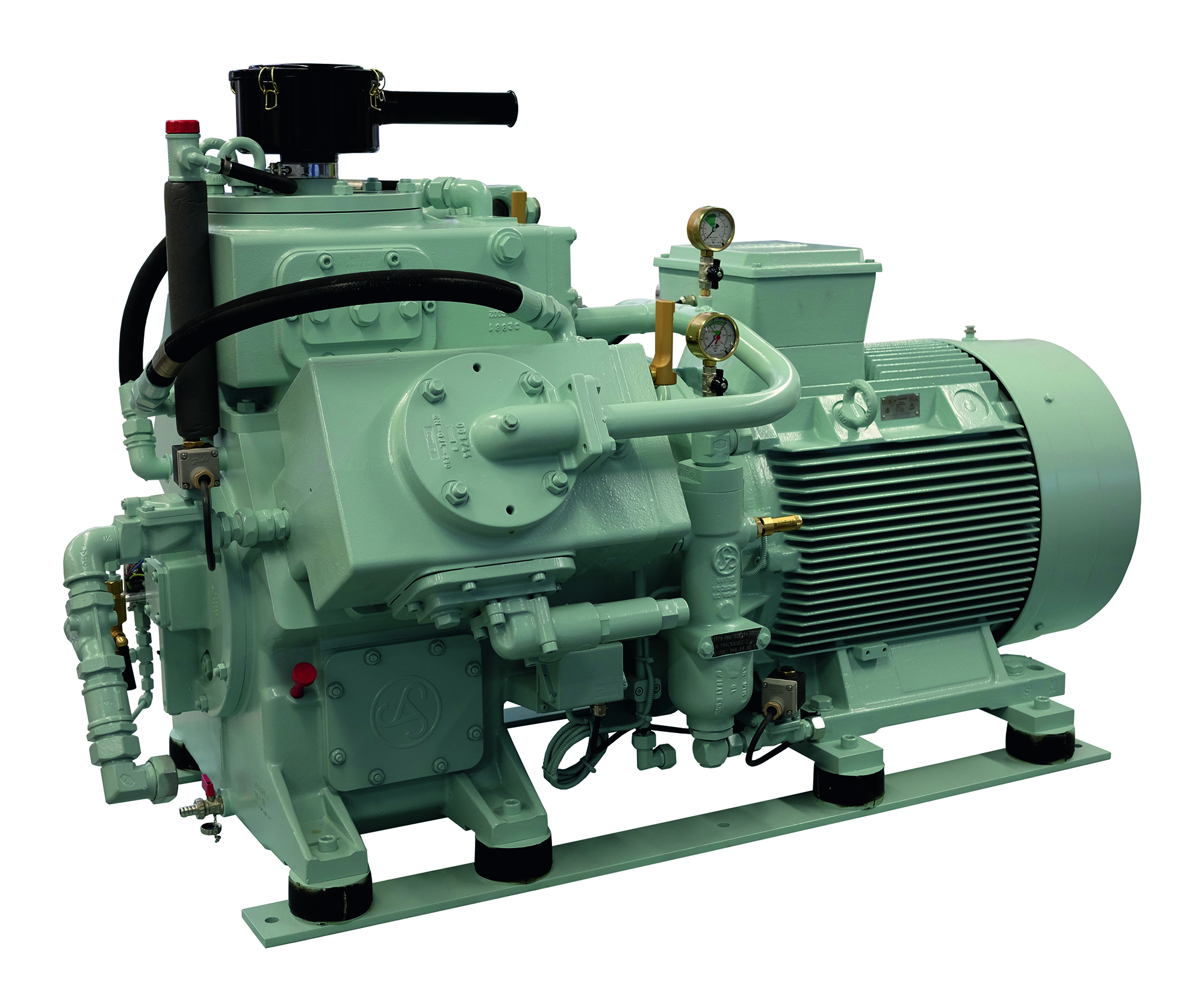

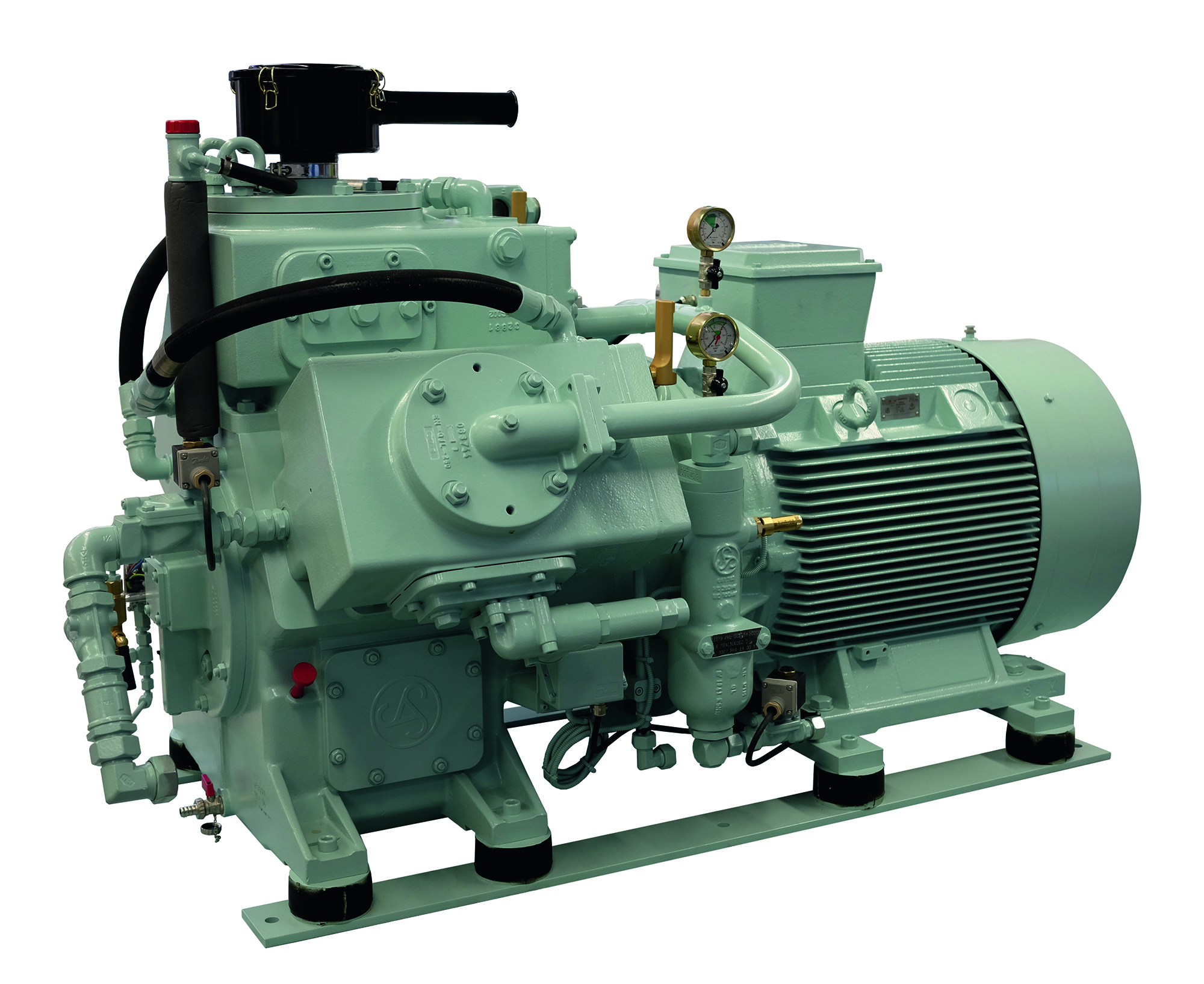

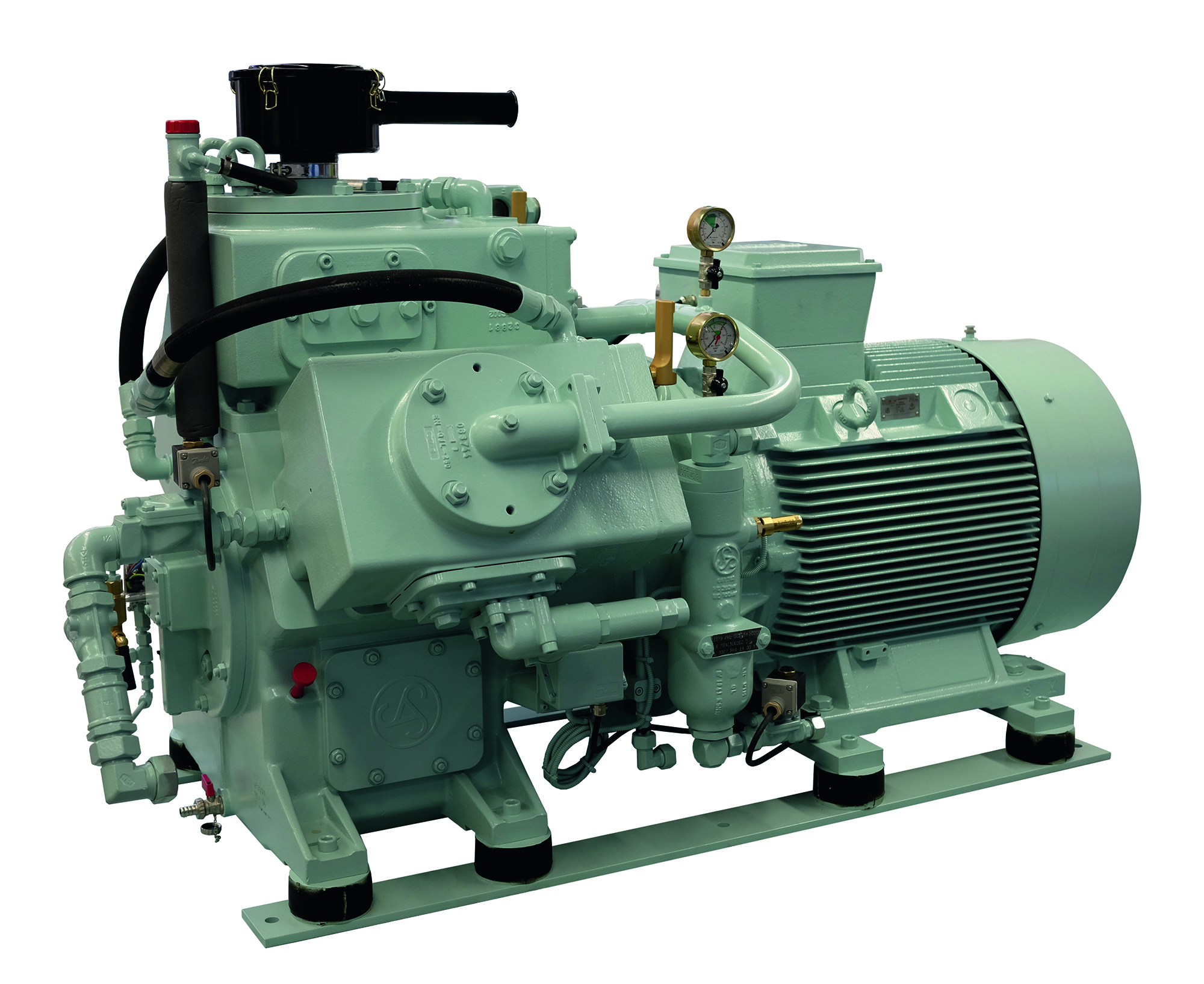

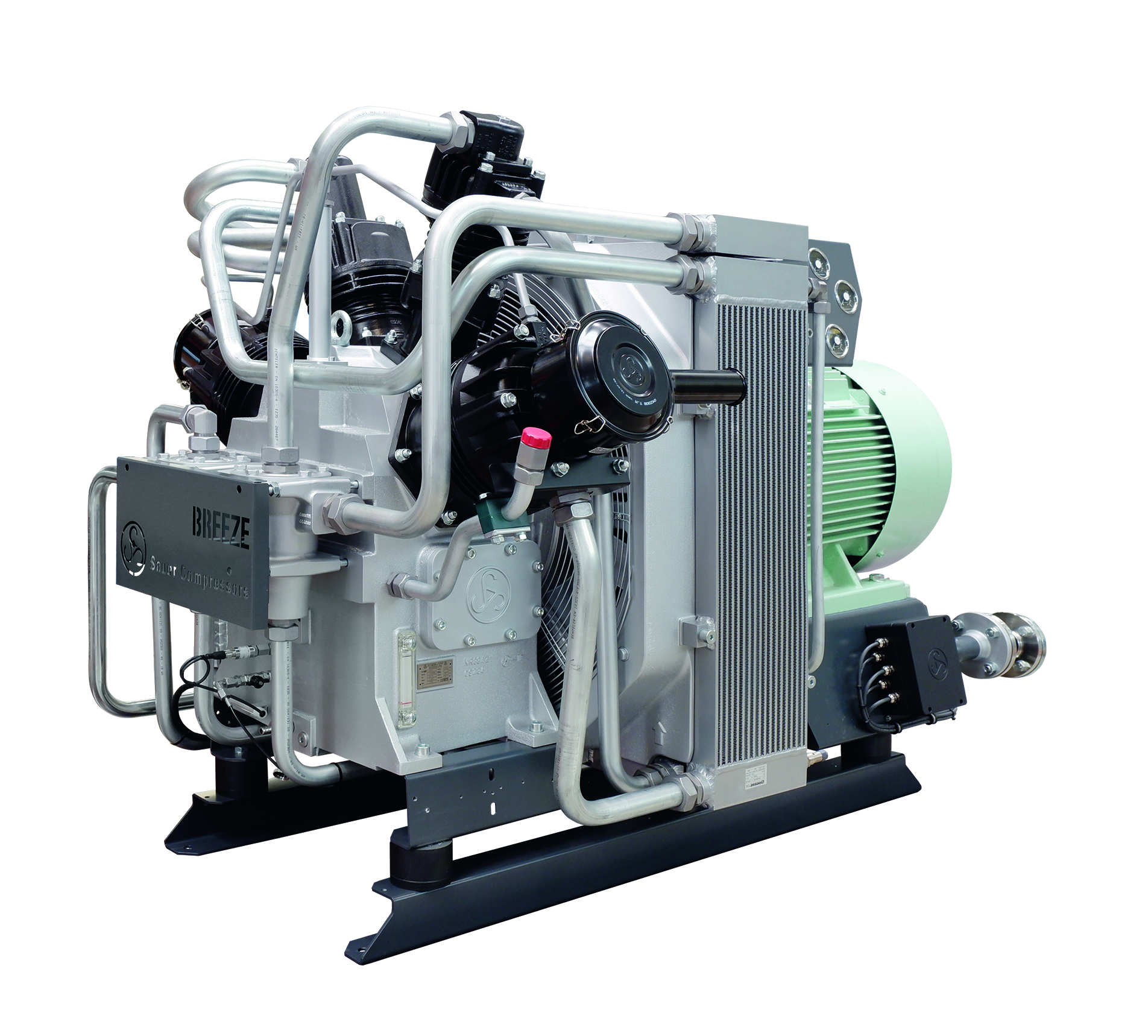

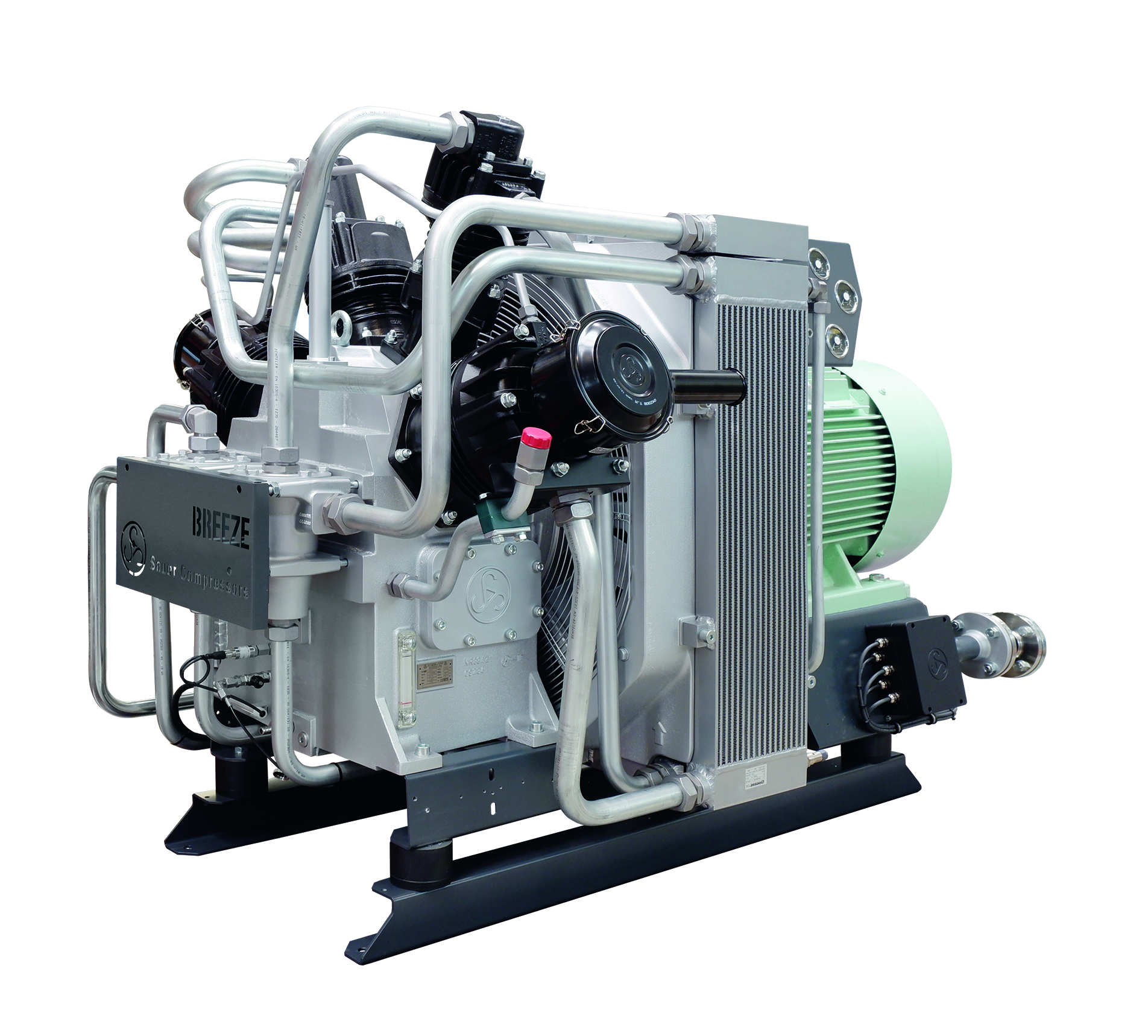

Pressure: 10 – 44 barg Volume Flow: 100 – 435 m³/h Rated Power: 35 – 105 kW Media: Air, Nitrogen

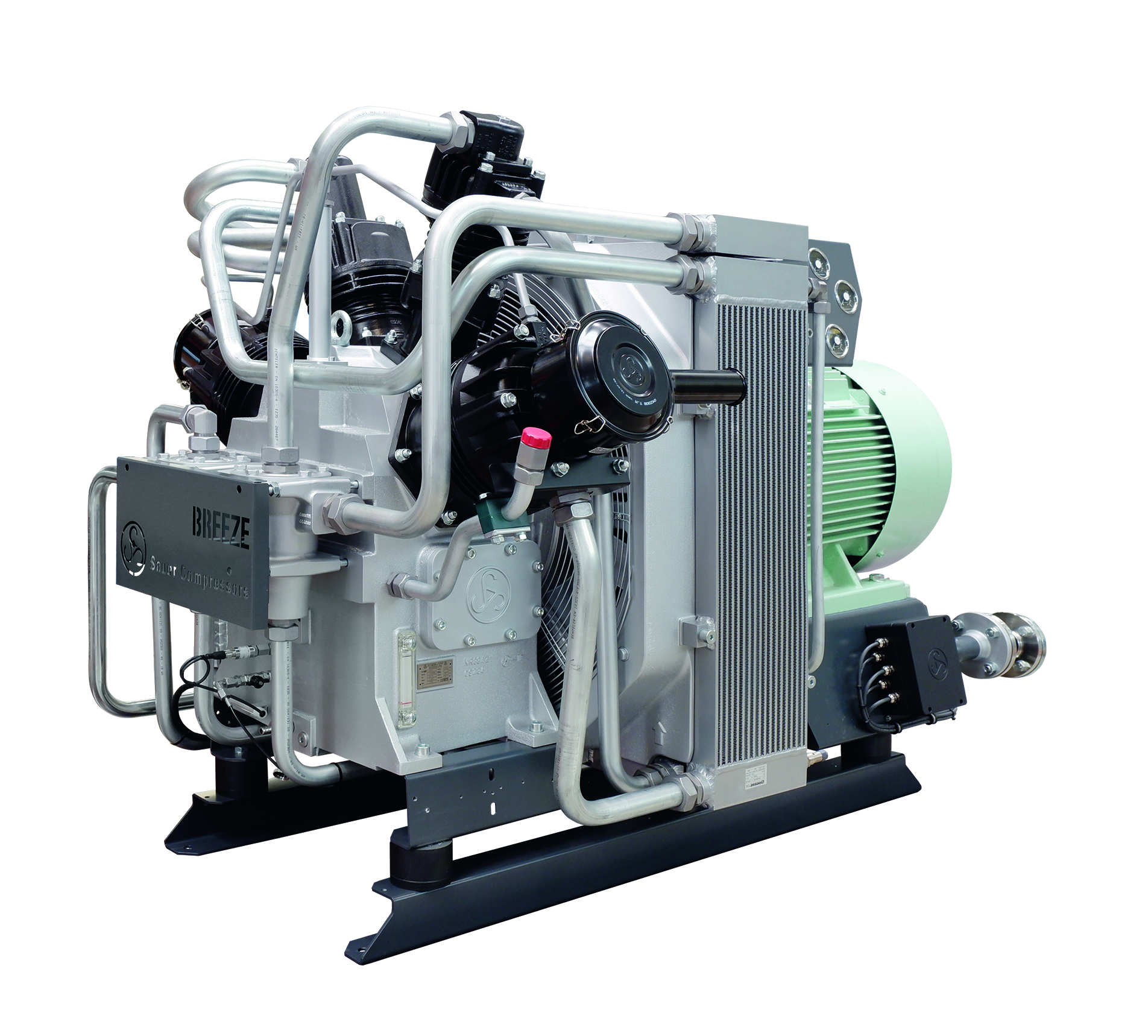

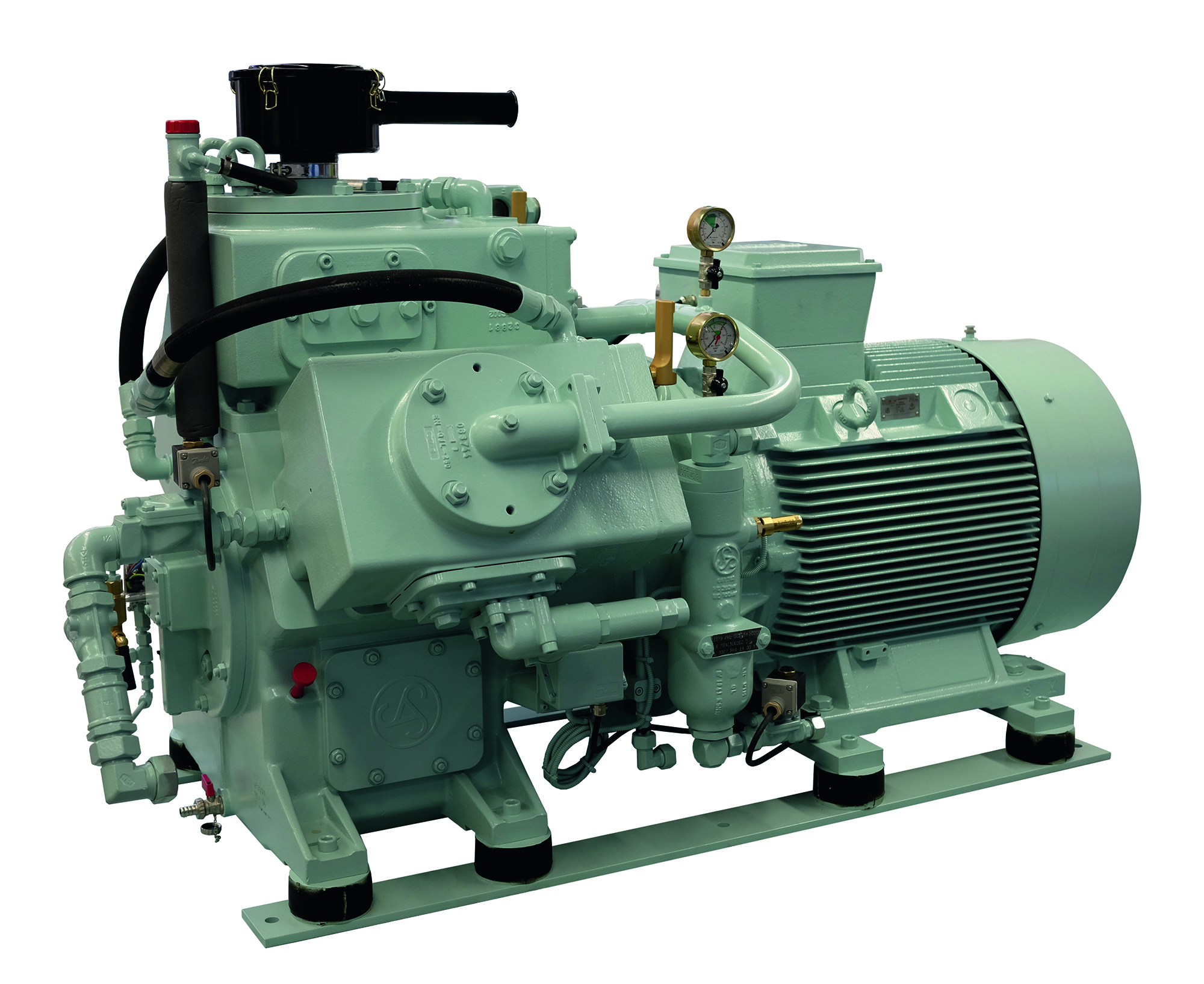

Pressure: 10 –100 barg Volume Flow: 60 – 395 m³/h Rated Power: 15 – 90 kW Media: Air, Nitrogen

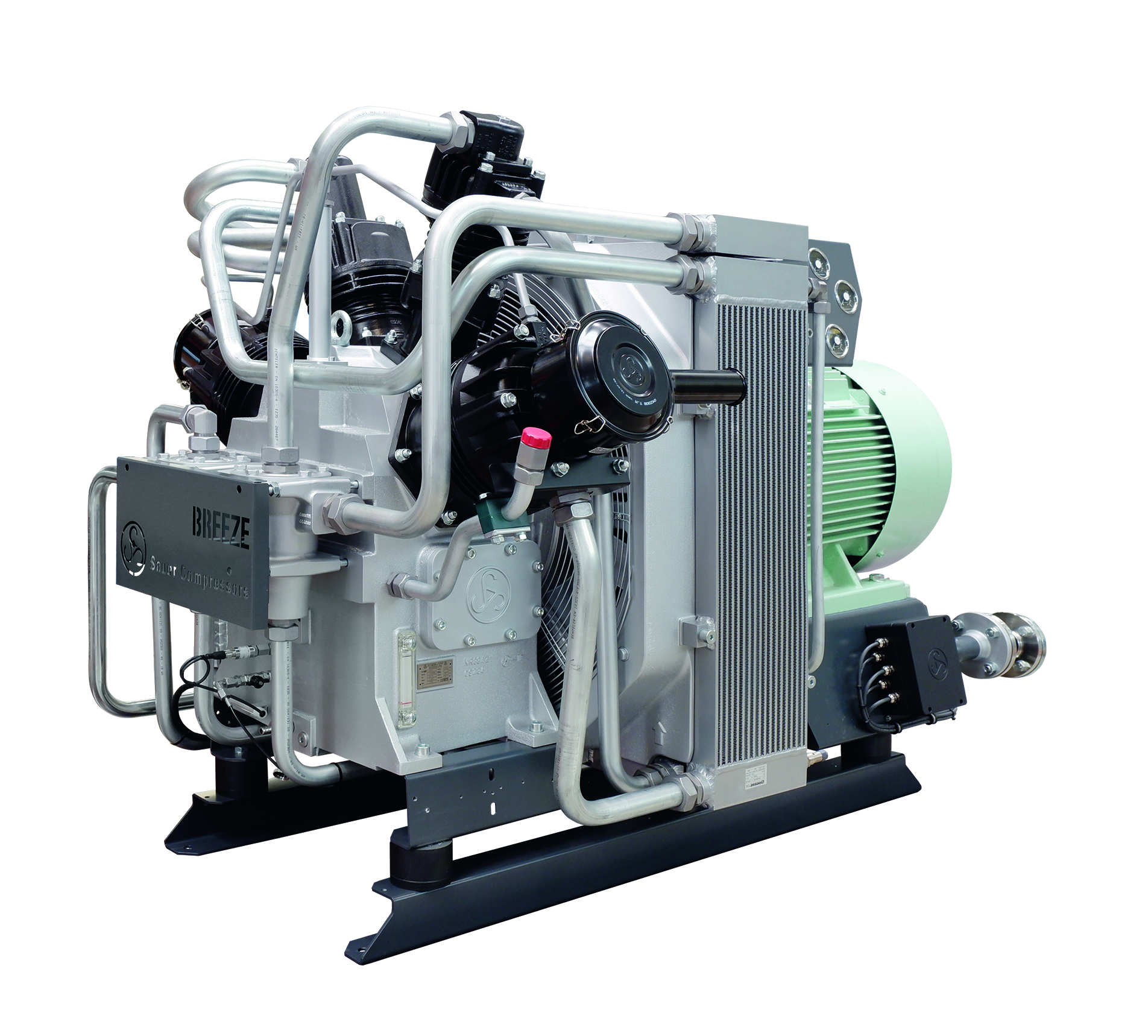

Pressure: Max. 500 barg

Suction Pressure: Max. 20 barg

Volume Flow: 200 – 1,000 m³/h

Rated Power: 120 – 250 kW

Media: Air, Nitrogen, Helium, Natural Gas, Bio-methane, Hydrogen

The SAUER 6000 series water-cooled compressors offer a blend of power and versatility with their modular design, featuring up to six cylinders and delivering pressures up to 500 bar with drive power reaching 230 kW. These large immersion piston compressors excel in challenging environments while providing maximum performance.

Key features include:

– Flexible compression unit configurations.

– Low-vibration operation thanks to W- or V-arranged compression units.

– Fully operational and foundation-free installation with integrated anti-vibration mounts to isolate noise.

– A high-performance water cooling circuit for each cylinder.

– Advanced protection systems with temperature and pressure sensors in every stage.

– Compression of multiple technical gases due to a gastight crankcase and minimal leakage.

– Variable frequency drive support for optimized process control.

Each compressor undergoes a full pressure test and includes a 3.1 inspection certificate, with guaranteed spare parts availability for at least 25 years.

| Type | Stages | Final pressure (barg) | Max. volume flow rate * @50 Hz (m³/h) | Max. volume flow rate * @60 Hz (m³/h) | |

|---|---|---|---|---|---|

| SAUER 6000 WP6305 | 3 | 50 | 685 | 781 | |

| SAUER 6000 WP6310 | 3 | 100 | 630 | 720 | |

| SAUER 6000 WP6335 B5-10 | 4 | 350 | 793 | 954 | |

| SAUER 6000 WP6442 | 4 | 400 | 500 | 580 | |

| SAUER 6000 WP6550 | 5 | 500 (He: 350) | 341 (He: 431) | 401 (He: 519) |

Pressure: 10 – 40 barg Volume Flow: 8 – 80 m³/h Rated Power: 3 –18.5 kW Media: Air, Nitrogen

Pressure: 10 – 44 barg Volume Flow: 100 – 435 m³/h Rated Power: 35 – 105 kW Media: Air, Nitrogen

Pressure: 10 –100 barg Volume Flow: 60 – 395 m³/h Rated Power: 15 – 90 kW Media: Air, Nitrogen

Pressure: 10 – 40 barg Volume Flow: 8 – 80 m³/h Rated Power: 3 –18.5 kW Media: Air, Nitrogen

Pressure: 10 – 44 barg Volume Flow: 100 – 435 m³/h Rated Power: 35 – 105 kW Media: Air, Nitrogen

Pressure: 10 –100 barg Volume Flow: 60 – 395 m³/h Rated Power: 15 – 90 kW Media: Air, Nitrogen

Pressure: 10 – 40 barg Volume Flow: 8 – 80 m³/h Rated Power: 3 –18.5 kW Media: Air, Nitrogen

Pressure: 10 – 44 barg Volume Flow: 100 – 435 m³/h Rated Power: 35 – 105 kW Media: Air, Nitrogen

Pressure: 10 –100 barg Volume Flow: 60 – 395 m³/h Rated Power: 15 – 90 kW Media: Air, Nitrogen