With more than 40 years’ experience in PET and 100 years in Compressors, SIAD MI introduced the new upgraded PET Compressor.

VITO Next: the “Next” generation

After the success of VITO, the first compressor specifically designed for the r-PET and PLA sectors, the “Next” generation is a high performing, reliable compressor built to be efficient, sustainable, and connected, at every level.

The lowest TOTAL COST of OWNERSHIP. With only 1 service every 8000 hours.

Since its launch, the VITO (acronym for Value, Innovation, Technology and Optimization) established the beginning of a “new era” in the world of air compression for blow molding machines and today SIAD MI can boast an achievement of installing over 6,000 compressors on all continents of the world.

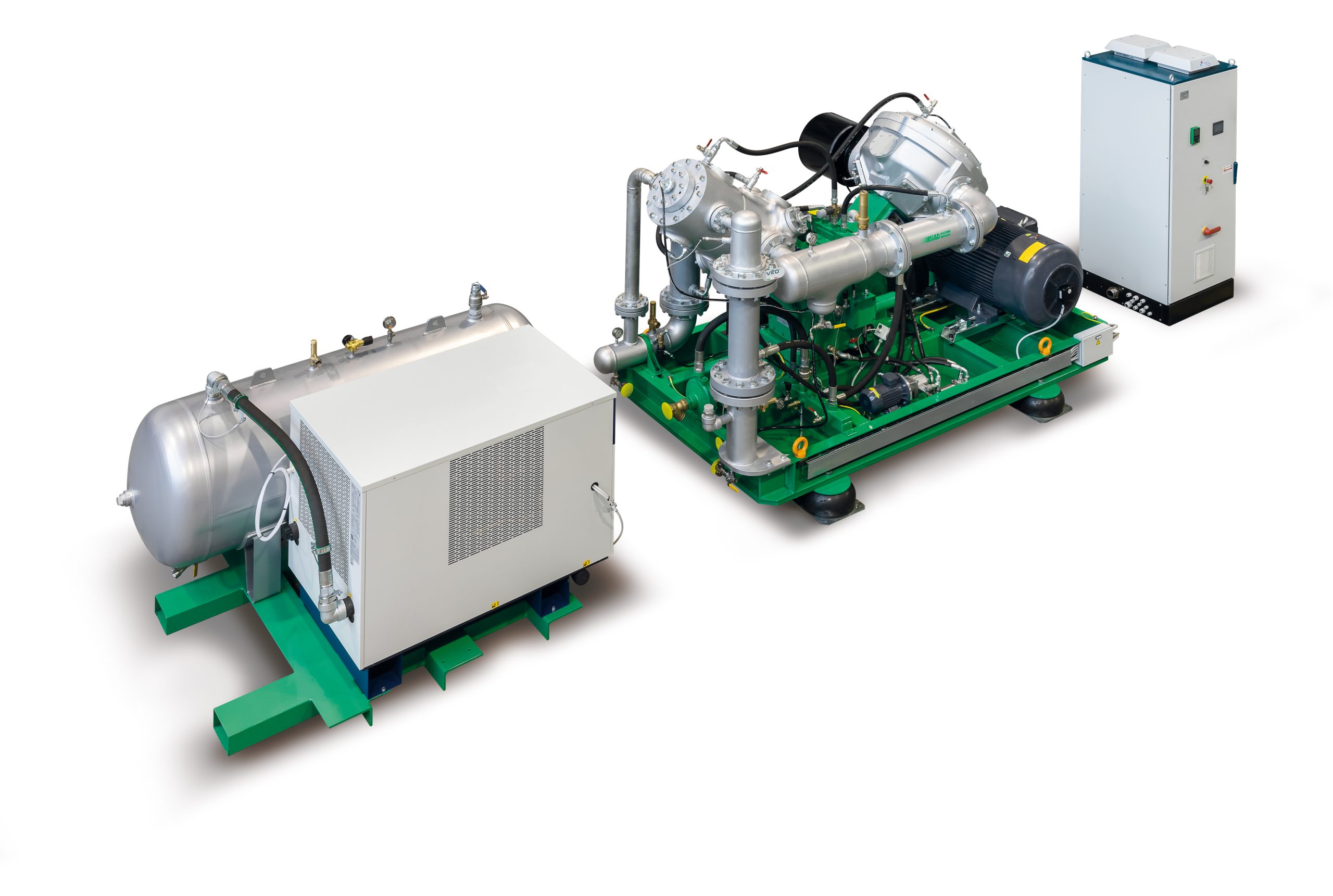

TECHNICAL STANDARDS / RANGES. Use picture: 0D7A5926 ratio 2_1+base

FAD Capacity 100 to 6000 m3/h

Working pressure up to 40 bar

Installed power up to 900 kW

Features

Extended lifetime

Greater reliability and improved performance

New options

ENERGY SAVING.

With an inverter drive, which regulates the frequency of the electric power supply, the compressor motor operates at variable speeds.

If the request for compressed air decreases, the 0-50-100% device works by excluding the upper effect of the first stage cylinder, by means of pneumatic valve unloaders, and therefore obtains a flow rate equal to 50% of the nominal value.

It is essential to know in detail the actual use of the compressors in order to study and define the most efficient working method for the system. For this purpose, SIAD Macchine Impianti (SIAD MI) offers the “Energy Saving Pack” which involves an analysis of the operation of the air compressors at the customers’ premises, with a detailed analysis of the energy consumption : this is then followed by a specific proposal for the installation of a control panel, or of a control panel plus a VSD. The main control panel manages up to 8 compressors simultaneously. The panel constantly calculates the total compressed air flow rate and the consumption of the electricity and therefore enables it in real time to adapt the compressors’ performance to the required changes.

Advantages:

This system allows the recovery of compressed air from the blow molder, with a consequent reduction in energy consumption for compression. For its customers, SIAD MI handles both the feasibility analysis and the implementation of this solution, which can be easily applied to compressors already installed.

The thermal energy produced by a SIAD MI compressor can be recovered for different purposes at the customer’s plant (eg : heating and auxiliary systems). In this situation too, SIAD MI handles both the feasibility analysis and the implementation of this solution for its customers. Depending on the model, the solution allows a recovery of between 30% and 80% of the thermal power of the compressor, plus providing a supply of water at temperatures of up to 90°C.

The SIAD Group’s engineering section comes under SIAD Macchine Impianti. Its many activities range from plant (reciprocating compressors for all types of gases, air separation units, ASUs, and natural gas liquefiers) plus global and ongoing management of support services.