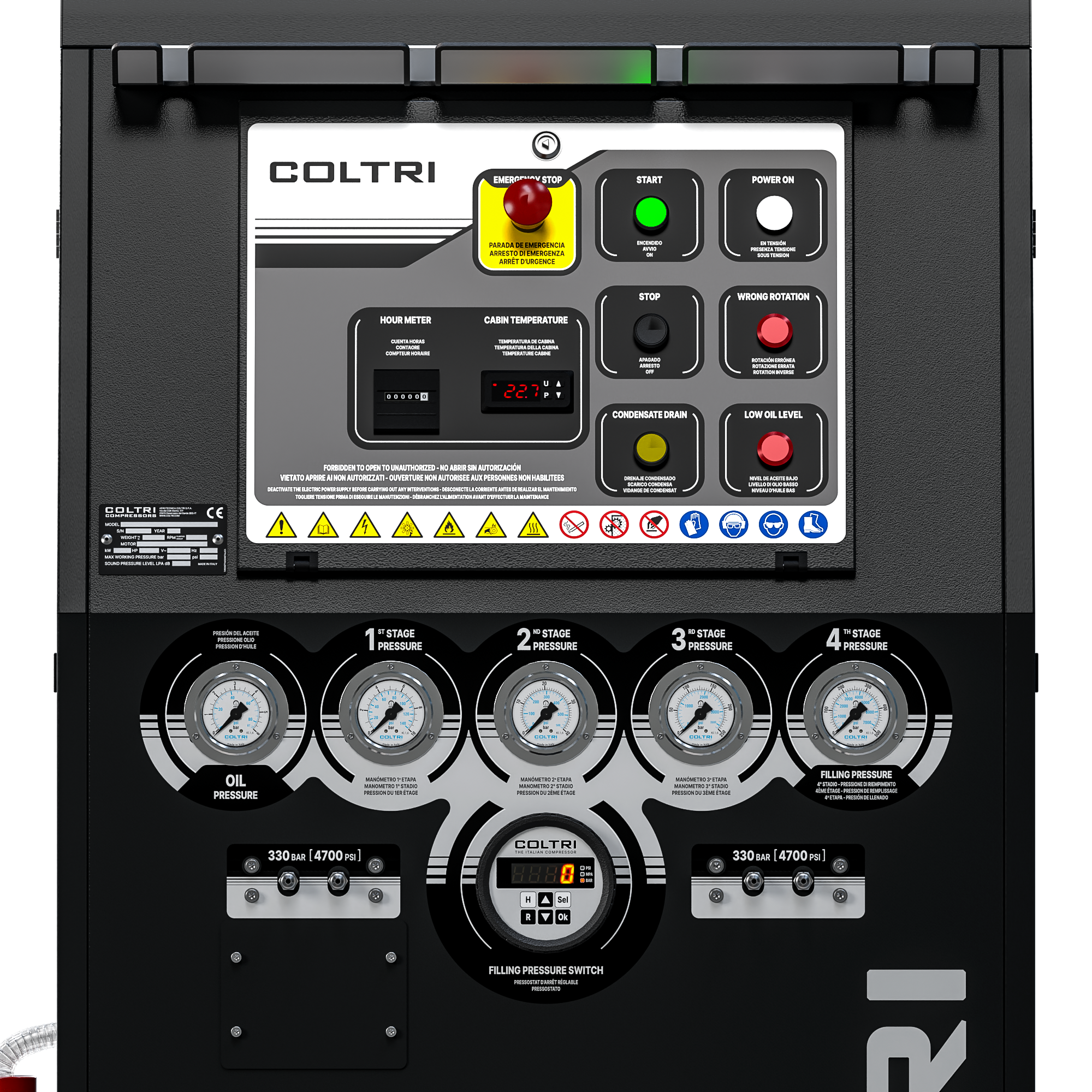

The OPEN model is designed to address professional demands for high charging capacities in hot, poorly ventilated, or tropical environments. It features four front filling connections for high-pressure hoses, an easy-to-use control panel, and an electric motor. The pumping group, selected from the four most powerful options, is positioned in the rear housing to enhance cooling efficiency. For extended filter lifespan, the Tornado high-pressure dryer is recommended. Optional features include the Presec system for monitoring filter saturation and the SAM system for multigas analysis and a remote charging panel.