COMPRESSED AIR EXPLAINED

What happens when we compress air?

Compressed Air is clean, safe, simple and efficient. There are no dangerous exhaust fumes or other harmful by products when compressed air is used as a utility. It is a non-combustible, non-polluting utility.

When air at atmospheric pressure is mechanically compressed by a compressor, the transformation of air at 1 bar (atmospheric pressure) into air at higher pressure (up to 414 bar) is determined by the laws of thermodynamics. They state that an increase in pressure equals a rise in heat and compressing air creates a proportional increase in heat. Boyle’s law explains that if a volume of a gas (air) halves during compression, then the pressure is doubled. Charles’ law states that the volume of a gas changes in direct proportion to the temperature. These laws explain that pressure, volume and temperature are proportional, change one variable and one or two of the others will also change, according to this equation

(P1 V1)/ T1 = (P2 V2)/T2

Where P=Pressure V=Volume and T=Temperature of the gas, 1 being an initial state before a change, 2 being final state after a change.

When applying this to a compressor, air volume (or flow) and air pressure can be controlled and increased to a level that suits the way it is being used. Compressed air is normally used in pressure ranges from 1 to 414 bar (14 to 6004 PSI) at various flow rates from as little as 0.1m3 (3.5 CFM – cubic feet per minute) and up.

FRAME 0

- Model : L02-L06

- KW : 2.2 – 7.5

- Flow @ 10bar : 0.18 to 0.89

FRAME 1

- Model : L07-L11

- KW : 7.5 – 11

- Flow @ 10bar : 0.97 – 1.39

FRAME 2

- Model : L15 – 22

- KW : 15 – 22

- Flow @ 10bar : 2.26 – 3.21

FRAME 2+

- Model : L23 – L26

- KW : 22 – 26

- Flow @ 10bar : 3.45 – 4.13

FRAME 3

- Model : L30 – L45

- KW : 30 – 45

- Flow @ 10bar : 5.01 – 7.00

FRAME 4

- Model : L55 – 75

- KW : 55 – 75

- Flow @ 10bar : 9.50 – 12.54

FRAME 5

- Model : L90 – 132

- KW : 90 – 132

- Flow @ 10bar : 15.51 – 21.51

FRAME 6

- Model : L160 – L290

- KW : 160 – 250

- Flow @ 10bar : 28.20 – 41.53

FRAME 6-2 Stage

- Model : L160e – L290e

- KW : 160 –

- Flow @ 10bar : 29.14 – 45.08

Compressed Air Explained

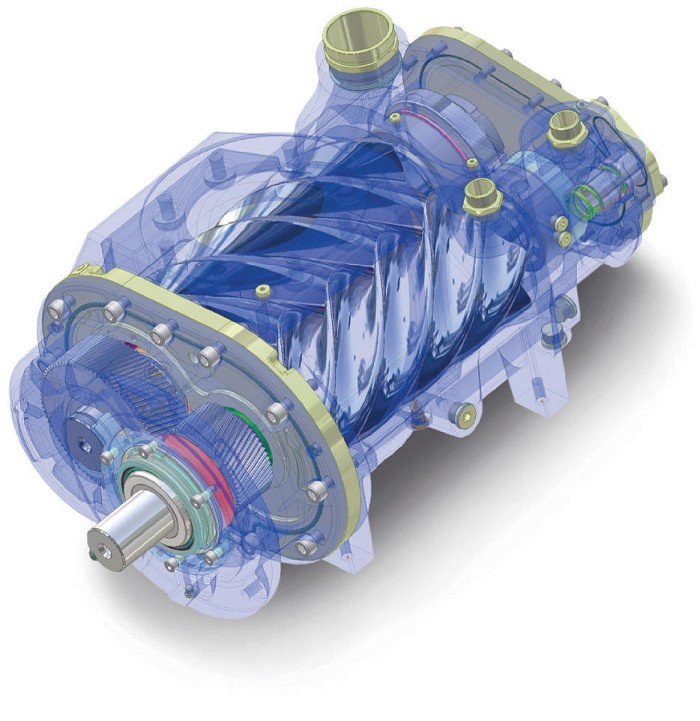

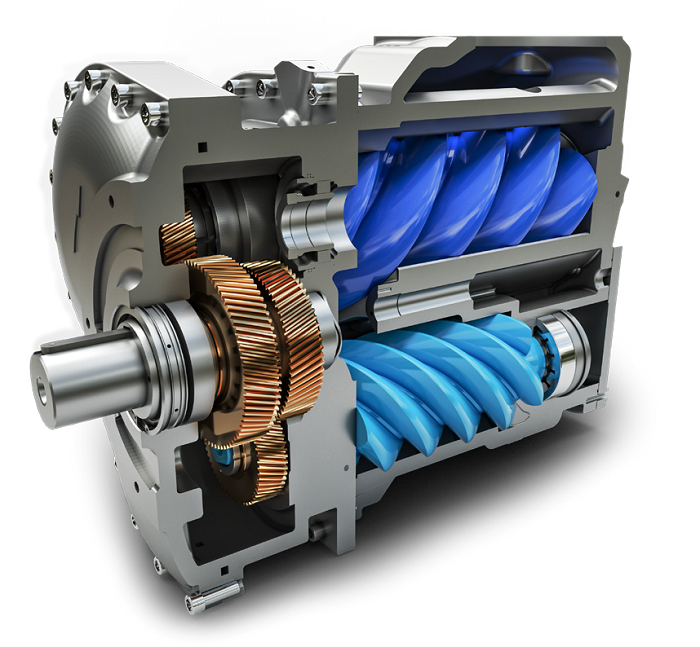

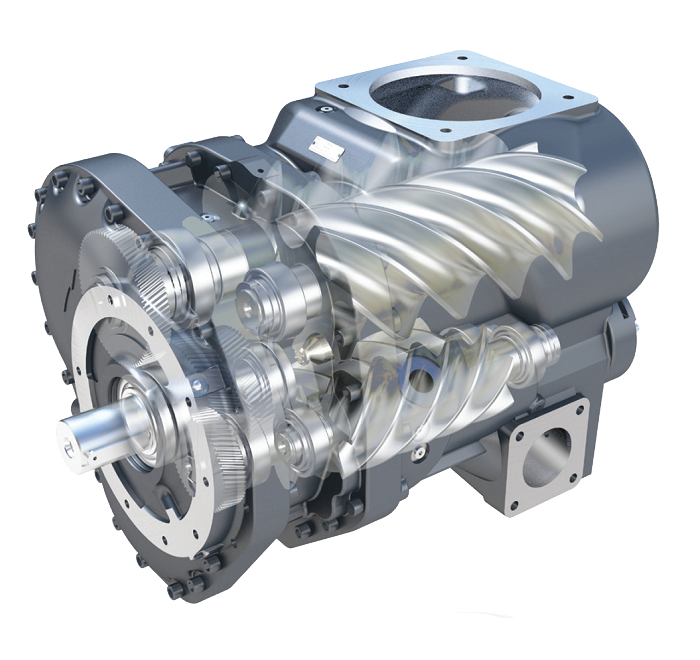

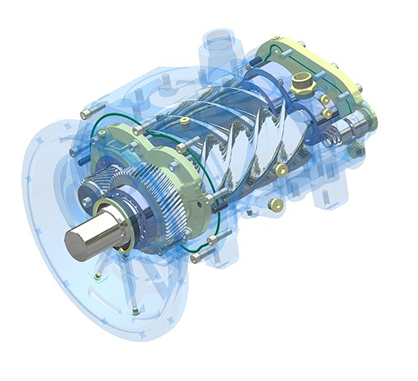

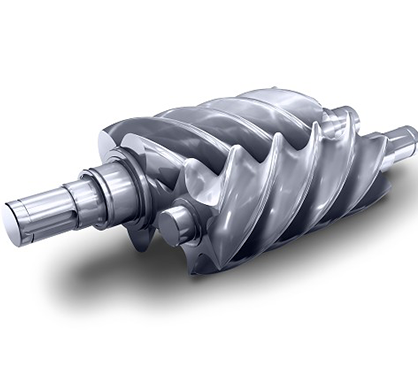

The screw compressor is a displacement compressor with pistons in a screw format; this is the predominant compressor type in use today. The screw compression element main parts comprise male and female rotors that move towards each other while the volume between them and the housing decreases. The pressure ratio of a screw is dependent on the length and profile of the screw and of the form of the discharge port.

The screw element is not equipped with any valves and there are no mechanical forces to create any imbalance. It can therefore work at high shaft speed and combine a large flow rate with small exterior dimensions.

Compression capabilities:

CompAir’s Rotary Screw range operates between 4kw to 250 kW (5 to 335hp), producing working pressure at 5 bar to 13 bar (72 to 188psi).

Typical types of applications:

Food Beverage, Brewing, Military, Aerospace, Automotive, Industrial, Electronic, Manufacturing, Petrochemical, Medical, Hospital, Pharmaceutical, Instrument air